| Quality + Study = | { |

Durability Accuracy Energy saving Reduced costs Increased productivity Competitiveness, etc. |

} | x heaters |

Infrared thermography is a technique that can be used in the plastics industry for process optimization and quality improvement, as well as in the development of new tools.

In the thermoplastic injection molding process, by means of thermographic images on freshly injected parts still in the mold or just removed, or on the mold surface itself, it is possible to obtain extensive information on the transformation process:

Report date:

10/10/2022

Company:

Resistencias

Ind. Maxiwatt

Client:

Address:

Site address:

Thermographer:

Contact person:

Parameters

Comments

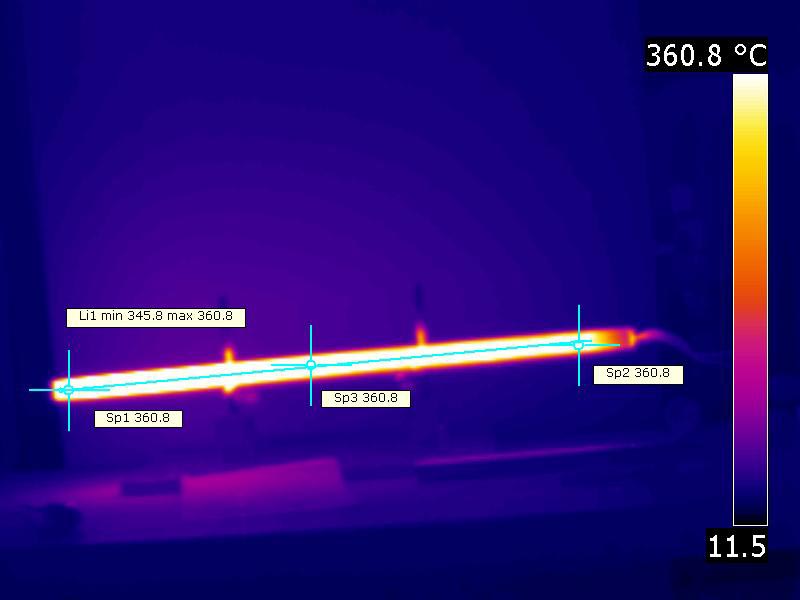

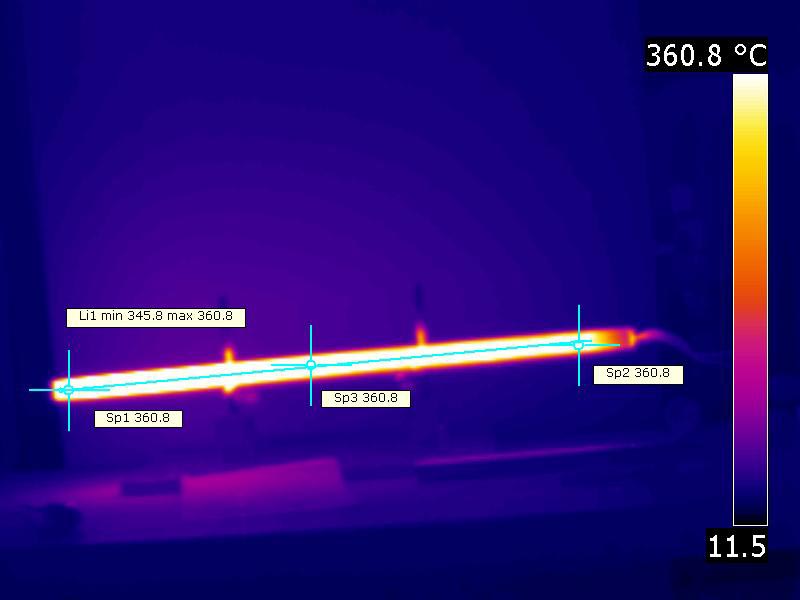

| Camera model: | FLIR T335 |

| Image date: | 10/10/2022 |

| Image name: | IR_138.JPG |

| Emissivity | 0.16 |

| Reflected temperature: | 20.0ºC |

| Object distance: | 1.0m |

Description

Cartridge Heaters Maxiwatt LLC performs a study with thermographic cameras to detect the efficiency of its heaters in the customer's mold or application, obtaining spectacular results in thermal precision with compensated heaters.

Thanks to this previous study of the mold or application, we achieve:

Cartridge Heaters Maxiwatt LLC provides a detailed written study of the thermographic process carried out by specialized technicians, using the best thermal cameras and advanced software available on the international market.