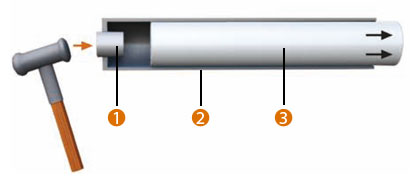

Cartridges should be as tight as possible.

When preparing to drill holes where the cartridge will be located, consider the following factors:

If possible, a hole should be drilled at the opposite end of the connections, in order to be able to extract the cartridge more easily.

1. Drilling for extraction

2. Mold

3. Cartridge

| Material | p | melting | Cp | Cf |

| Steel | 7.8 | 1400 | 0.12 | 60 |

| Aluminum | 2.7 | 600 | 0.23 | 94 |

| Bronze | 78.4 | 900 | 0.10 | |

| Foundry | 4.2 | 1150 | 0.13 | 30 |

| Stainless Steel | 7.8 | 1600 | 0.12 | 56 |

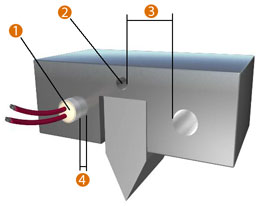

1. Cartridge

2. Probe

3. Maximum 15 millimeters

4. Maximum adjustment